G400 Rear Loader

G400 High Compaction

Offering the largest hopper in the business

Better looking and longer lasting

Component Pre-paint

To save time and production cost, some competitors build complete assemblies, then paint them afterwards. However, this often leaves behind inconsistent paint finishes, gaps in paint coverage, unsightly painted hydraulic and electrical lines and more. With our component pre-paint process, we paint individual components before assembly—levers, handles, brackets and more—then we assemble the complete unit, already fully painted.

Our component pre-paint process helps ensure a better-looking, longer-lasting, higher-quality finish on all painted surfaces with more consistent coverage providing greater corrosion resistance over time. Most importantly, component pre-paint delivers the quality paint finish you deserve and puts your company image in the best light possible.

G400 Rear Loader Features

Packs up to 1200 lbs. per cubic yard

4-cubic-yard hopper – Largest in the industry

Linkage packer design – No shoes, rollers or slides to wear out

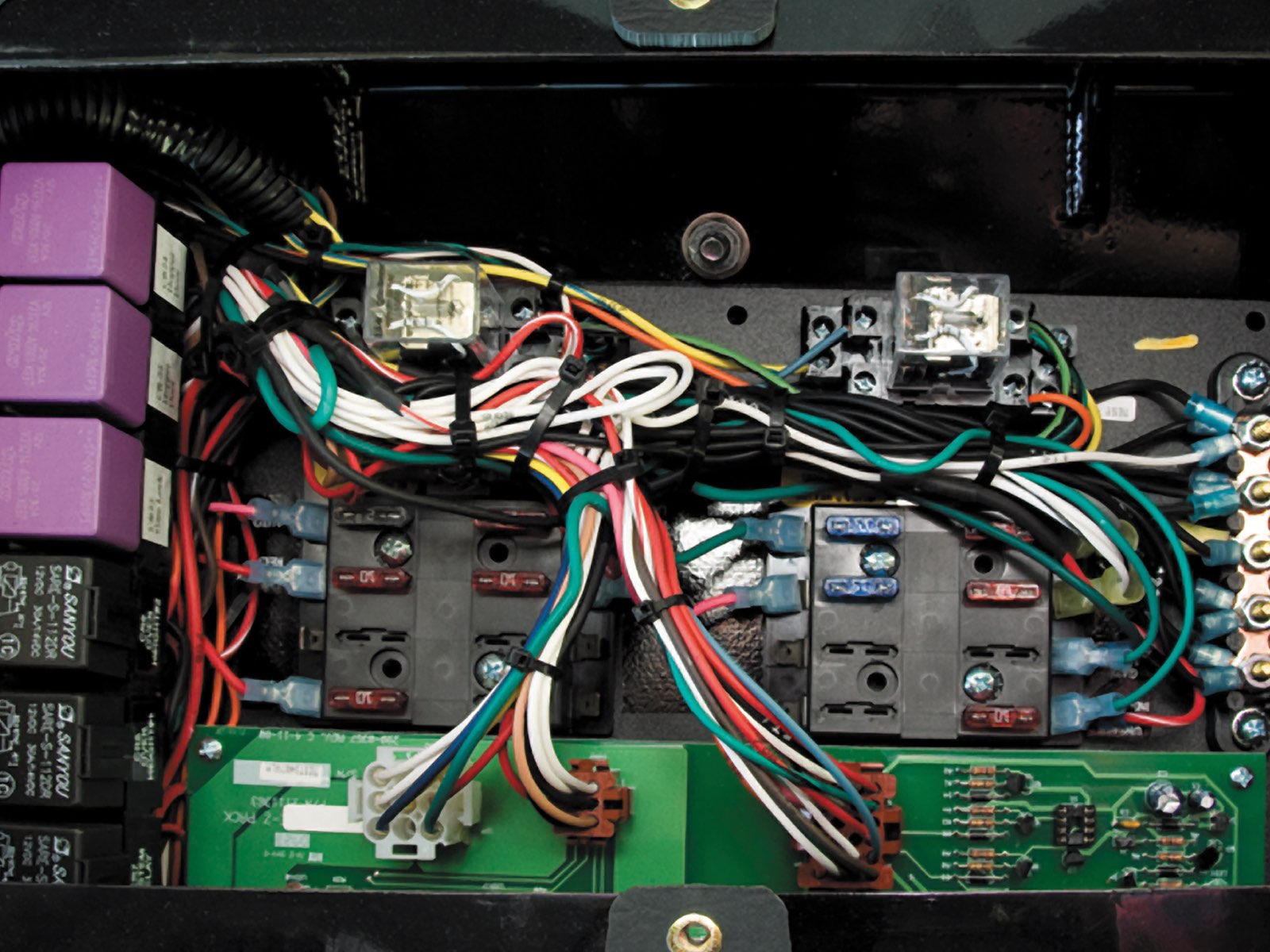

Zinc-dichromate plated tubing with unpainted hoses and fittings

Flush tailgate panels – Resists trash build-up to reduce rust and corrosion